The steel casting sector is consistently evolving, pushed by the desire for increased precision, improved top quality, and minimized defects. With this landscape, the stress casting device plays an important purpose. nonetheless, for Vacuum gold casting machine quite possibly the most demanding apps, a specialised kind of casting equipment is needed: the vacuum force casting machine. This article explores the exceptional advantages of these equipment, focusing on how they enrich the precision and top quality of metal casting, especially for precious metals like gold and platinum.

Table of contents:

the benefits of Using Vacuum strain Casting equipment for High-Quality Results

How Vacuum tension Casting improves the Accuracy of Gold, Platinum, and various Metals

Why Vacuum force Casting is important for large-Precision Industries

The Advantages of applying Vacuum Pressure Casting devices for top-high quality outcomes

Vacuum strain casting devices present a big breakthrough in comparison with classic casting solutions. The Main advantage lies inside the elimination of air pockets and gasoline porosity in the casting. By executing the casting system beneath a vacuum, the molten metal is permitted to stream additional freely and entirely fill the mildew cavity. This leads to denser, stronger castings with much less inner defects. Moreover, the applying of strain throughout the solidification period really helps to further more consolidate the metal, minimizing shrinkage and strengthening the general high-quality. This would make vacuum pressure casting ideal for producing intricate and complex patterns in which even the smallest imperfections can compromise the performance or aesthetic enchantment of the final item.

How Vacuum force Casting improves the Accuracy of Gold, Platinum, and Other Metals

The high worth and one of a kind Homes of important metals like gold and platinum necessitate exceptional casting precision. Vacuum gold casting device technological know-how is specifically built to meet up with these demanding needs. The vacuum ecosystem not merely helps prevent oxidation on the molten metal and also makes sure a clear and regular casting method. This is particularly crucial for gold, which can certainly tarnish or create floor defects if exposed to air during casting. What's more, the controlled pressure applied all through solidification promotes uniform grain composition and minimizes the potential risk of cracking or distortion. This ends in castings which have been dimensionally exact, have fantastic area finish, and keep the specified mechanical Houses.

Why Vacuum tension Casting is Essential for High-Precision Industries

High-precision industries, for example aerospace, professional medical machine producing, and significant-conclusion jewellery manufacturing, count on vacuum force casting to accomplish the stringent high quality standards required for his or her applications. the chance to develop castings with restricted tolerances, minimal defects, and consistent substance properties is paramount in these sectors. as an example, while in the aerospace business, vacuum tension cast components are used in critical motor elements where dependability and efficiency are non-negotiable. likewise, in health care machine producing, vacuum tension casting guarantees the biocompatibility and structural integrity of implants. the advantages extend to jewellery making in addition, wherever intricate patterns and flawless finishes are important for generating substantial-benefit pieces. in the long run, vacuum force casting gives the mandatory Command and precision to fulfill the demanding prerequisites of such industries. As evidenced by solutions just like the TAKJ-VC-W obtainable at https://taeantech.com/products/takj-vc-w, these machines are exclusively built to cater into the precision needed by vacuum tension casting procedures.

In summary, vacuum pressure casting equipment are indispensable equipment for obtaining high precision and remarkable high quality in metal casting. The mix of vacuum atmosphere and managed pressure removes frequent casting defects, enhances substance Attributes, and makes certain dimensional precision. For industries demanding the best levels of overall performance and trustworthiness, buying vacuum pressure casting technologies is not only a option but a necessity. Consider the unique specifications of one's application and discover the various vacuum stress casting methods accessible to unlock new alternatives in steel casting and elevate the caliber of your final goods.

Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Tatyana Ali Then & Now!

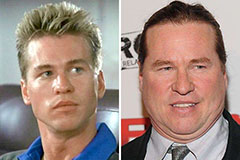

Tatyana Ali Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Christina Ricci Then & Now!

Christina Ricci Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now!